1.Production Process

1)Steelmaking process Flow Chart

Blast Furance+Hot Metal Ladle Truck+KR Hot Metal Treatment+Converter+LF Refining Furnace+RH Vacuum Degassing Furance+Con-cast

2.Rolling Process Flow Chart

Reheating Furance+High-pressure Water Descaling+Edger Mill+Roughing Mill+Finishing Mill+Accelerated cooling+Hot Leveler+Marking

and Spray Printing+Cooling Bed+On-line UT+Crop Shear+Double-side Trimming Shear+Cut-to-length Shear+Measurement+Marking and Spray

Printing+Cold Leveler/Heat treatment

3.Heat-Treatment Flow Chart

Plate+Shot Blasting+Quenching Furance+Quenching Machine+Tempering Furance+Warm Leveler+Cooling Bed+Cutting+Cold

Leveler+Finishing&Packaging

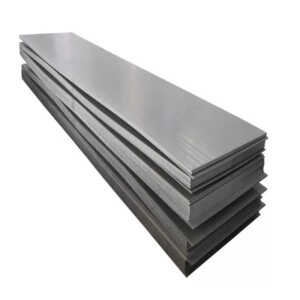

4.Thickness and Width

Thickness:4.5mm-150mm

Width:1600mm-4100mm

5.Main Grade

Germany: XAR400,XAR450,XAR500,XAR600,Dillidur400,Dillidur500

Belgium: QUARD400,QUARD450,QUARD500

France: FORA400,FORA500,Creusabro4800,Creusabro8000

Baosteel: B-HARD360,B-HARD400,B-HARD450,B-HARD500

HBIS: NM360,NM400,NM450,NM500

Finland: RAEX400,RAEX450,RAEX500

Japan: JFE-EH360,JFE-EH400,JFE-EH500,WEL-HARD400,WEL-HARD500

6.Chemical Composition&Property

| Grade | C | Si | Mn | P | S | Al | Cr+Ni+Mo | Nb+V+Ti |

| NM400 | 0.10-0.40 | 0.20-0.40 | 1.00-2.00 | ≤0.015 | ≤0.003 | ≥0.020 | MAX 0.9 |

Trace Amount |

| NM450 | 0.10-0.40 | 0.20-0.40 | 1.00-2.00 | ≤0.015 | ≤0.003 | ≥0.020 | MAX 1.2 | |

| NM500 | 0.10-0.40 | 0.20-0.45 | 1.00-2.00 | ≤0.015 | ≤0.003 | ≥0.020 | MAX 1.5 | |

| NM550 | 0.10-0.50 | 0.20-0.45 | 1.00-1.50 | ≤0.015 | ≤0.003 | ≥0.020 | MAX 2.0 | |

| NM600 | 0.10-0.50 | 0.20-0.45 | 1.00-1.50 | ≤0.015 | ≤0.003 | ≥0.020 | MAX 2.5 | |

| XCHD400 | 0.10-0.30 | 0.20-0.40 | 1.00-2.00 | ≤0.015 | ≤0.003 | ≥0.020 | MAX 0.1 | |

| XCHD450 | 0.10-0.40 | 0.20-0.40 | 1.00-2.00 | ≤0.015 | ≤0.003 | ≥0.020 | MAX 0.9 | |

| XCHD500 | 0.10-0.40 | 0.20-0.45 | 1.00-2.00 | ≤0.015 | ≤0.003 | ≥0.020 | MAX 1.5 |

7.

| Grade | Size(mm) | RP0.2(Mpa) | Rm(Mpa) | A50(%) | AKV,(ºC) | KV2(J) | HBW | ||

| NM400 | 100 | 1233 | 1337 | 15 | -20 | 35 | 37 | 42 | 415 |

| NM450 | 60 | 1345 | 1434 | 9.5 | -20 | 72 | 59 | 58 | 455 |

| NM500 | 50 | 1608 | 1706 | 10.5 | -20 | 43 | 50 | 45 | 495 |

| XCHD400 | 35 | 1025 | 1161 | 17.5 | -40 | 52 | 45 | 40 | 413 |

| XCHD450 | 30 | 1281 | 1400 | 10.5 | -40 | 45 | 48 | 52 | 453 |

| XCHD500 | 6 | 1465 | 1529 | 13.5 | -40 | 24 | 24 | 22 | 515 |

8.Cerifications

9 Classification Society

ISO 9001 Certified

9.Packaging&Shipping

Seaworthy packaging by container or bulk cargo vessel

Delievery time:stock size within 7days;new material within 40days

10.Our services

We can cut and bend steel plate according to customer’s requriement or drawing,packaging according to customers’ request

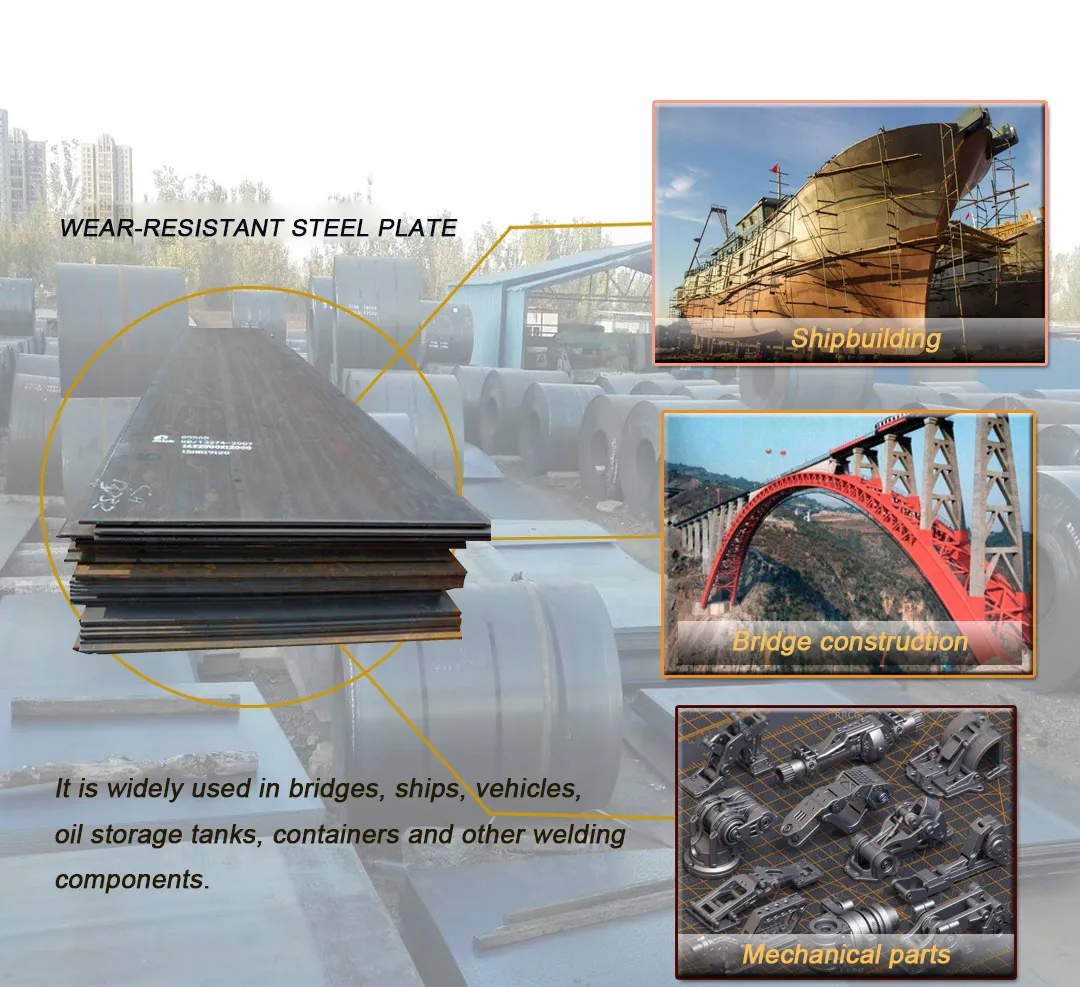

11.Application

By adopting the combined chemical composition design of low carbon,low sulfur,low phosphorous and micro-alloy,by applying the

offline quenching and other advanced automation technologies,our wear resistant(Abrasion Resisant) plate are popular at home and

abroad. Mainly used for thermal Power plant,Coal Mines ,Cement Mills,Loading Machinery,Mining Machinery,Project

Machinery.Metallurgical Machinery,Wear resistant plate also can be applied in Sand Mill Cylindrical Shell, Vane, Mechanical Parts

used in yard and port, Bearing Structure Parts etc.